Certifications & Capabilities

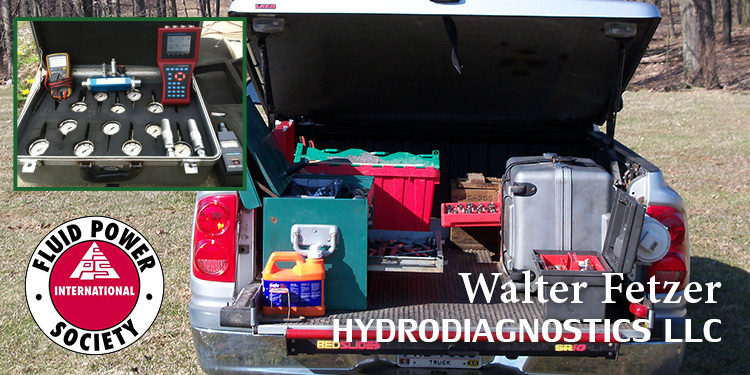

Walter Fetzer of Hydrodiagnostics is Certified by the International Fluid Power Society (IFPS) as a Certified Fluid Power System Designer (Certificate Number 23865), as a Certified Fluid Power Hydraulic Specialist (Certificate Number 16086-R2) and as a Certified Fluid Power Electronic Controls Specialist (Certificate Number 19807-R). Further information on IFPS Certification can be found below, and at the IFPS wesite by following this link: http://www.ifps.org/docs/certification/default.aspx

Fluid Power System Designer

System Designer (CFPSD) is defined as an expert with advanced knowledge, skills and experience in hydraulic and electronic controls with responsible charge of systems level design. Responsible Charge is direct control and personal supervision of fluid power system design work. System Designer is an expanded credential focusing on advanced, system level hydraulic and electronic controls expertise along with verifiable industry experience.

Fluid Power Hydraulic Specialist

Hydraulic Specialist (CFPHS) certification is for those designing systems and writing specifications, sizing and selecting hydraulic components for mobile and industrial operating machinery. Hydraulic specialists draft schematics using standard fluid power symbols. Hydraulic specialists design systems which are drafted to fluid power essential practices supported by National and International Standards. Hydraulic Specialist certification requires a three (3) hour written test.

Summary of the capabilities of a Hydraulic Specialist:

- Read circuit diagrams, size components and understand function as used in hydraulic systems.

- Analyze load & motion. Determine and perform calculations for the work profile to move loads (force, distance, work, torque, speed, velocity and power.)

- Provides ISO cleanliness level for each system.

- Specifies filtration to maintain ISO cleanliness level.

- Specifies flushing and commissioning.

- Specifies Sampling and diagnostic ports.

- Size and specify hydraulic cylinders and motors.

- Understand operating curves for proportional control valves. Identify components on the amplifier card.

- Specify hydraulic reservoirs to meet system requirements.

- Specify hydraulic accumulators for system operation.

- Calculate heat loss and size heat exchangers

- Identify properties of hydraulic fluids and compatibility with seal materials.

- Understand the use and application of biodegradable fluids.

- Analyze and trouble shoot hydraulic systems (pressure, flow, heat, vibration, noise, and cycle time).

- Recognize the basic electrical control systems.

- Understand ladder logic.

- Match programmable logic controller (PLC devices with application).

- Instructs others in operations and maintenance.

- Promotes safe working conditions with pressurized systems.

Fluid Power Electronic Controls Specialist

Electronic Controls Specialist (CFPECS) certification is designed to review and test understanding, specification, and application of the full breadth of electronics used in the fluid power industry from simple sensors and limits to HMIs, controllers, and networks. It includes a brief review of applicable pneumatic and hydraulic principles, as well as in-depth examples of the electronics for both mobile and industrial fluid power equipment. The Electronic Controls Specialist certification requires a three (3) hour written test

Summary of the capabilities of an Electronic Control Specialist:

- Fluid Power Systems

- Electronic and Electrical SolutionsIFPS

- Input/Output Devices

- Applying Control Theory

- Interacting with Controllers

- Utilize Industrial Networks

- Instructs others in operations and maintenance.

Further Capabilities

In addition , Hydrodiagnostics, LLC offers the following services:

- Providing trouble shooting and supervising required replacement, repair, or adjustment of systems or components.

- Setting up and testing systems and components.

- Recommending modification to circuit & components to improve performance.

- Supervising system installation, flushing & commissioning.

- Taking fluid samples, reading, and explaining lab reports.

- Establishing ISO cleanliness level for a system.

- Devising the Target Cleanliness Chart.

- Understanding accumulator use & operation.

- Understanding hydrostatic drives.

- Setting pump load sensing and compensator controls.

- Understanding basic electrical controls and their application.

- Calculating decompression volume.

- Understanding regenerative circuits and their use.

- Understanding sequence & counterbalance circuits and associated valving.

- Training users on their particular systems and explaining fuid power concepts.